Sample Environment & Delivery (SED)

SED CONTACT INFO

Ray Sierra

Staff Scientist

Office: B57-2040B

(650) 926-3148

rsierra@slac.stanford.edu

Bob Sublett

Area Manager

Office: B751-205C

(650) 926-3184

sublett@slac.stanford.edu

Injector Characterization Lab (ICL)

(650) 926-4638

The LCLS Sample Environment and Delivery (SED) Department, part of the Biological Sciences Department, is responsible for making all necessary equipment and training for onsite sample characterization, manipulation, and delivery to beam, available to all potential users. SED is currently in the process of building and acquiring a broad inventory of sample delivery equipment which is detailed on our equipment tab below.

The Injector Characterization Lab is currently open to users for optimizing sample delivery, allowing users to test sample delivery feasibility prior to proposal submission and to optimize sample delivery prior to beamtime. Use of the ICL is expected to reduce experimental setup time and greatly increase the efficiency of LCLS beamtime.

Supported Methods

The table below summarizes the current sample handling capabilities at the LCLS. We are currently in the process of developing new sample delivery techniques, and users are encouraged to contact the Sample Environment Department to discuss requirements unique to their experiment - we are flexible.

| Technique | Size | Vacuum | Ambient |

|---|---|---|---|

| Liquid Jets | 1 µm - 10 µm | ✅ | ✅ |

| 20 µm - 500 µm | ⛔️ | ✅ ♻️ | |

| Liquid Sheets | < 1 µm | ✅ | ✅ ♻️ |

| 1 µm - 10 µm | ⛔️ | ✅ ♻️ | |

| 10 µm - 250 µm | ⛔️ | ✅ ♻️ | |

| Liquid Drops | 40 µm - 6 0 µm | ⛔️ | ✅ |

| Double Flow Focusing | All available sizes | ✅ | ✅ |

| Electrospinning (MESH) | All available sizes | ✅ | ✅ |

| High Viscosity | All available sizes | ✅ | ✅ |

| Aerosols | All available sizes | ✅ | ⛔️ |

✅ Available ⛔️ Not Available ♻️ Recirculation is available at some endstations.

Descriptions of Sample Delivery Methods

Liquid Recirculation

High flow rate experiments operating in ambient air or in a helium enclosure can be operated in a closed-loop recirculating system when the sample permits. Cylindrical liquid jets from 20 micrometer diameter and larger and liquid sheets of any thickness from a few 10’s of nanometers to several hundred micrometers can be recirculated. The minimum volume of sample needed to fill the swept volume of our recirculating system is typically a few ml for smaller jets, Larger sheets operating at greater than 150 ml/minute require a peristaltic pumping system with a higher swept volume. Details can be found on the pump section of our Equipment tab.

Cylindrical Liquid Jets

Single fluid “Rayleigh Jets” can be used for experiments in which larger diameter, >20 micrometers, jets with high flow rates are acceptable. These jets are often used for pump-probe spectroscopies at the XPP and XCS endstations with a recirculating system in a helium enclosure. They can also be operated in vacuum without recirculation however their reliability is much higher at pressures closer to atmospheric. The nozzles are made of straight walled polished quartz tubing but other materials are available. These jets are fairly reliable and users are usually able to operate on their own after a short training session.

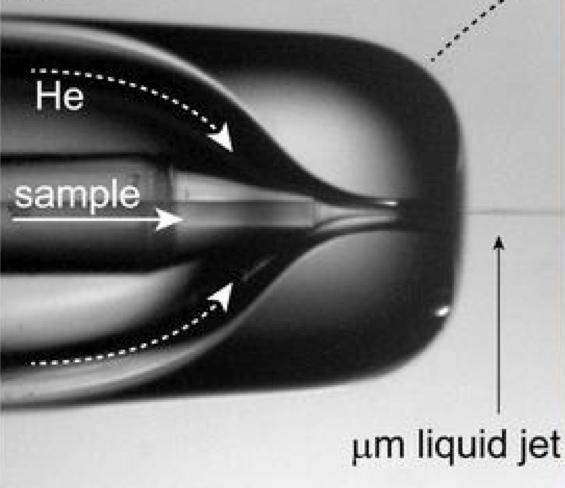

Gas Accelerated, GDVN, or flow focused jets can be made much smaller than single fluid nozzles. They are commonly operated in vacuum for serial crystallography experiments – the reduced jet diameter, 1 to 10 micrometers reduces the background scatter. Flow rates can be as low as 10 microliters per minute but typically these nozzles are run at 20 microliters per minute in order to get longer, more stable jets for the experiments.

Liquid Sheets

- >10 micrometers. Straight walled nozzles are used to make sheets from 13 micrometers thick and larger. As with cylindrical jets, these have fairly high flow rate and are operated in ambient conditions.

- 1 to 10 micrometers – Converging nozzles are useful for making

- < 1 micrometer – Gas accelerated nozzles make ultra-thin sheets that can be operated in vacuum or atmosphere.

Aerosols

Aerosols are made by nebulization of liquids. GDVN, Electrospray, or gas assisted electrospray have been used. An aerodynamic lens stack made by Uppsala is owned by SLAC and is available to users. Aerosols are used primarily for single particle imaging. Solutions must have high particle density and low amounts of salts, buffers, or any nonvolatile material that cannot be evaporated from the sample.

Other Methods

Other SLAC sample delivery methods - descriptions coming soon.

- Flow Focusing & Mixers

- Drop on Demand

- High Viscosity Injection LCP

- Electrospray MESH

- Gas Sources and Cells

Non-SLAC User-owned Equipment

There are some methods not owned by SLAC that have been used at SLAC and may be available through collaboration.

- Acoustic Levitation

- Rowed Runner

- Dipstick

Equipment Available for Use with Your Experiment

| Item | Manufacturer | Model | Quantity | Lower Limit (mL/min) | Upper Limit (mL/min) | Remote Controllable? |

|---|---|---|---|---|---|---|

| Paristaltic Pump | Cole-Parmer | Masterflex L/S | 2 | N/A | N/A | ❌ |

| HPLC Pump | Shimadzu | LC10Ai | 1 | 0.001 | 9.999 | ❌ |

| HPLC Pump | Shimadzu | LC20AD | 4 | 0.0001 | 10 | ✅ |

| HPLC Pump | Shimadzu | LC20AT | 1 | 0.001 | 10 | ✅ |

| HPLC Pump | Shimadzu | LC20AP | 1 | 0.01 | 150 | ✅ |

| Sample Deliver System | SLAC SED Lab | SDS | 2 | N/A | N/A | ✅ |

| Water Chiller/ Circulator | ThermoTek | T255P 625Watt | 1 | N/A | N/A | ❌ |

Sample Shaker Video

Nozzles

We can provide nozzles for gas jets, liquid jets (Recirculating type), gas accelerated liquid jets (aka GDVN or Flow Focusing nozzle), and drop on demand/pulsed jets from our nozzle inventory. Specialized nozzles can also be made with advanced notice.

Gas dynamic virtual nozzles (GDVNs) are the most commonly used nozzles for serial crystallography experiments. They consist of concentric capillaries where the inner capillary carries the sample, and the outer capillary carries a high pressure gas to accelerate the sample forming a jet. Jet diameters are typically from 3 to 5 micrometers but can be made much smaller depending on the sample. Currently the GVN used at LCLS are produced through additive manufacturing using a Nanoscribe 3D printer in collaboration with Rick Kirian at Arizona State University.

High viscosity jets are produced from nozzles very similar to those described above but require higher operating pressure. We have a high pressure sample injector, known as the LCP injector, consisting of a pressure amplifier, sample reservoir and nozzle that can operate up to 15 kPsi (>1000 bar). Typical nozzle diameters are between 50 and 100 micrometers and can be provided by SED. The LCP injectors were purchased from Uwe Weierstall at Arizona State University.

Rayleigh jets can be produced from straight channel nozzles down to 20 micrometers. Liquid may be recirculated for Rayleigh jet nozzles operating at ambient pressure. Mixing from up to 4 channels is also possible with Rayleigh jets.

Our drop on demand system is a MicroFab droplet dispenser that can be timed to the arrival of the FEL pulse, greatly reducing sample consumption.

Sample Delivery System (SDS)

Our sample delivery system handles sample switching and remote control of all sample injection parameters. It consists of sample reservoirs and shakers, sample and gas handling manifolds, regulators and flow meters. All aspects of the system can be controlled remotely in EPICs, and the system is duplicated for use in multiple hutches and the ICL. The system is modular so that it can be configured to meet specific experimental needs, and can be used to deliver sample to most injectors. The EPICs control panel, pictured below, illustrates the sample and gas routing. Typically high pressure gas is used to drive a hydraulic piston that forces the sample through the system, however, HPLC pumps are also available for this purpose.

Beamtime Support

SED staff are available to perform and/or assist with sample delivery activities during beamtime but support requests must be received early in the experiment planning process. Depending on the level of difficulty and duration of the experiment we can support some or all of the scheduled beamtime. For example, Protein Crystal Screening, PCS, experiments are often short duration and high-difficulty experiments. In this case SED staff may be present for the entire PCS shift if requested. Recirculating liquid jet spectroscopy, by comparison, typically is fairly easy to operate and runs for 5 shifts. In this case, SED staff will setup the equipment and stay with the user group until they are confident that they can operate without assistance.

Safety Training and Access

Please contact Bob Sublett for safety training and access.

User Equipment Training

It is advisable to do some offline training with sample delivery equipment in advance of your experiment. SED provides workspace and equipment for users to practice using the same sample delivery equipment that will be used during the experiment. Please contact Bob Sublett to arrange training.

Feasibility Checks

Feasibility is an important consideration in the proposal review process. We encourage you to bring us your feasibility questions as far as possible in advance of submitting a proposal. If the feasibility of an experiment is cannot be definitely determined after consulting SED, nearly any SED equipment can be made available for offline tests.

Injector Characterization Lab

Setup and Test Space

Located midpoint between the Near and Far experimental halls, the Injector Characterization Laboratory serves as a setup area, a testing and training space, and as the stockroom for sample delivery components and hardware. A brief training session is required after which 24/7 badge access is granted. Specific equipment or bench space can be reserved in advance (please contact Area Manager Bob Sublett). Otherwise unreserved and not-in-use space is open to anyone with badge access.

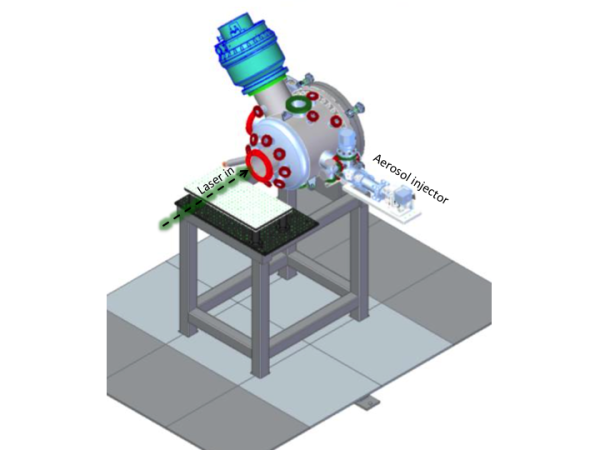

FEL Simulator

The FEL Simulator, an all-optical endstation that mimics aspects of an LCLS experimental sample environment. Located in the ICL, the FEL Simulator consists of a large high-vacuum chamber, coupled to multiple laser sources piped in from the adjacent Research Laser Lab (RLL). It is designed to accommodate most sample delivery tools, including a state-of-the-art aerosol injector recently purchased by LCLS. The laser of choice will be tightly focused in the center of the chamber where it will interact with the sample. Diagnostics include a time-of-flight detector for analyzing the remnants of photoionized sample, as well as high-speed cameras and optical detectors for capturing scattered photons and images of jet breakup etc. Controls will be implemented through EPICS and will be identical to those used during real experiments. The FEL Simulator will be able to accommodate crossed molecular beams which, coupled with ion detection, will be invaluable for optimizing conditions in the dynamic molecular reaction microscope highlighted for LCLS II.

Injector Testing stations

There are two, small, test stations to test in vacuum injectors such as GDVN or LCP. Each station consist of a rough-pumped, windowed KF40 chamber, with a zoom 7.5x to 30x microscope, liquid flow meter, and manually controlled self relieving regulators. Nitrogen and helium are normally provided and other gases may be provided with advance request.